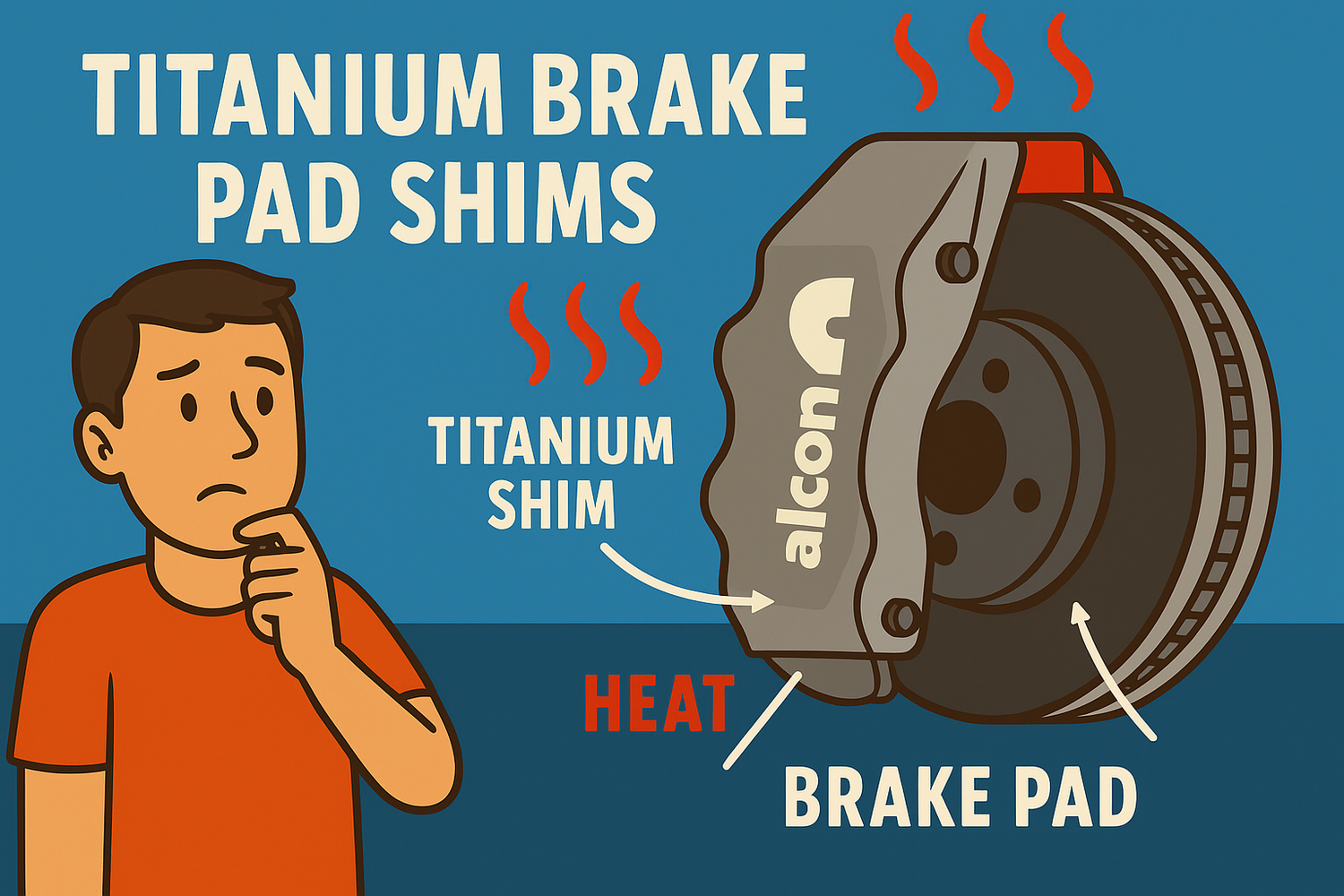

Titanium Brake Pad Shims: Do They Work? In-Depth Guide & Data

If you’re chasing more consistent brakes on long downhill runs, spirited mountain drives, or track days, you’ve probably heard of titanium brake pad shims (also called heat shields). This guide explains what they are, how they work, where they help (and where they don’t), and backs it all with credible data so you can decide if they belong on your car.

What are Titanium Pad Shims?

Titanium pad shims are thin plates that sit between the brake pad backing plate and the caliper pistons. Their job is simple: slow heat conduction into the caliper so seals and brake fluid stay cooler for longer.

Titanium (especially Grade 5 Ti-6Al-4V) has very low thermal conductivity, around 6.7–7.5 W/m·K, compared to standard steels at roughly 20 W/m·K. Lower conductivity means heat moves much slower, which is exactly what you want in a heat barrier.

The Data: How Much Cooler Do They Keep the Caliper?

- In a controlled lab test, the caliper-side temperature dropped from 286°C to 206°C with titanium shims — a 79°C reduction at the pad/caliper interface.

- EBC’s development notes report significant reductions in heat transfer through the pad into the caliper, with the primary goal of protecting caliper seals and brake fluid.

Bottom line: titanium shims don’t change how much heat the brakes create; they simply delay how quickly heat reaches the caliper, which can mean the difference between a firm pedal and boiled fluid on a hot Aussie track day.

Why Lower Caliper Temperatures Matter

1. Protecting Caliper Seals

Seal life is directly affected by time spent at high temperature. Keeping calipers cooler extends seal life dramatically.

- If calipers regularly reach 200°C, plan to reseal every other event.

- At 220°C+, rebuild intervals must be even shorter.

2. Protecting Brake Fluid

Even high-quality DOT 4 brake fluids have a dry boiling point of ~312–328°C and a wet boiling point of ~195–206°C. By lowering caliper temperature, titanium shims help prevent vapour lock and keep pedal feel consistent over long sessions.

Why Titanium Instead of Steel?

Heat travels through conduction from the pads to the pistons. Titanium slows this transfer far more effectively than standard steel.

- Titanium (Ti-6Al-4V): ~6.7 W/m·K

- Steel: ~20 W/m·K

This makes titanium an ideal material for a heat shield, reducing heat soak into the caliper and protecting seals and fluid.

Real-World Benefits

- Lower caliper and seal temperatures during repeated hard stops.

- Improved pedal consistency across a session by reducing fluid temperature rise.

- Extended service life for seals, dust boots, and brake fluid.

Where Titanium Shims Help the Most

- Track days and motorsport with multiple hot laps.

- Heavy performance cars on high-grip tyres generating extreme brake energy.

- Long mountain descents in hot Australian summers.

- Cars with limited cooling airflow or factory calipers near their limits.

What Titanium Shims Won’t Do

- They won’t fix pad fade: If pads overheat, friction still drops. Choose the correct compound for your driving style.

- They don’t reduce total heat: They simply slow how fast it reaches the caliper.

- They aren’t anti-squeal shims: Retain factory damping shims where needed to prevent brake noise.

Installation Notes

- Most are laser-cut Grade 5 titanium and reusable if undamaged.

- Fit between the pad and pistons with full, flat contact across the backing plate.

- Combine with high-temp brake fluid, correct pad compound, and cooling ducts for best results.

Who Should Skip Titanium Shims?

If your car is a pure street daily driver and you never experience brake fade or a soft pedal, focus on:

- Fresh fluid changes every 12 months.

- Proper pad bedding for quiet, consistent braking.

- Correct pad compound suited to your driving style.

Key Takeaways

- Titanium shims reduce caliper temperatures by up to 79°C.

- They protect caliper seals and brake fluid from excessive heat soak.

- Best used alongside correct pads, fluid, and ducting for maximum effect.

We stock titanium pad shims for popular performance calipers. Combine them with the right pads and fluids to ensure reliable braking for both street and track use.

Shop our full range of brake pads and performance braking upgrades here.